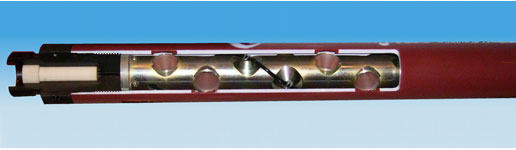

Perforating Gun Pipe

Perforation is an extremely important technology in the petroleum exploration and development. It is also one of means to improve the recovery of oil and gas wells. In perforating operations, perforating bullets need to use perforating gun pipes or perforating gun barrels as gun carrier to position the perforation direction and protect oil casing in the explosion process. The requirements for its quality and performance, especially its transverse impact toughness requirements are very strict. Steel tube for perforating gun is mainly used for producing perforating gun body in oil and gas wells. The standards and steel grade include API SPEC 5CT, 33Mn2V and 32CrMo4. Perforating gun pipe is composed of gun-barrel, spearhead, gun breech, sealing element and other components.

Advantages1. Steel tube for perforating gun is made from 25Mn2V and 32CrMo4 (30CrMo) materials. After testing, its performance, dimension and inspection all comply with the set requirements. JST products have high dimensional control accuracy and stable performance.

2. The size of cold rolled perforating gun pipe will change a little after heat treatment and straightening, especially the pipe end diameter will produce a certain amount of reduction. Cutting two pipe ends can solve the problem of pipe end reduction so as to achieve customers’ requirements for the dimensional accuracy and to meet the requirements of technical specifications for steel tube for perforating gun.

3. The cold drawing unit of JST perforating gun pipe is configured with one φ76 perforated pipe mill, four sets of φ50 perforation units, 28 sets of 5-120 tons cold drawing machines, straightening machine, testing equipment, etc.

4. We own two professional heat treatment production lines configured with advanced heat treatment equipment, making furnace temperature is equal or less than 5℃ and ensuring stable heating temperature. We also configure the rotating spray cooling system to fully guarantee water quenching uniform cooling of steel tube for perforating gun. There are two sets of Siemens electronic control six roller straightening machine to ensure the straightness of tubing and casing after heat treatment. The two heat treatment production lines for perforating gun pipe can process tubings and casings with the length of equal or less than 13.5 m (φ114-φ406 mm) and the length of equal or less than 12.5 m (48 mm to 180 mm). The annual productions of tubing are 150,000 tons and 50,000 tons.

5. Our proprietary grades allow us to offer the best solutions for each customer’s particular well conditions.

6. JST steel tube for perforating gun (perforating gun pipe) is manufactured to the most exacting quality standards. We hold a global ISO 9001 registration for our operations, which follow a uniform quality policy and apply a rigorous quality management system.

| Steel Grade | JST110Q, 25Mn2V, 30CrMo, 32CrMo4, etc. |

| Item | Allowable Deviation |

| Outer Diameter (mm) | 0 to +0.79 |

| Wall Thickness (mm) | -10% to 12.5%·S Deviation less than 1 mm |

| Curvature | ≤ 1.0mm/m |

| Outer Diameter (mm) | Wall Thickness (mm) |

| 60.32 | 5.0 |

| 68.5 | 5.50, 6.30 |

| 73.02 | 5.51, 7.82 |

| 83.0 | 9.0 |

| 88.9 | 6.45, 7.1, 8.0, 8.8, 9.19, 10.0, 12.0 |

| 96.0 | 10.0 |

| 101.6 | 7.0, 9.0, 9.5, 10.0, 11.0 |

| 108.0 | 8.0 |

| 114.3 | 10.0, 12.5, 13.0 |

| 127.0 | 9.5, 11.0, 12.5 |

| 159.0 | 12.0, 12.5, 13.0 |

| 178.0 | 12.0, 12.5 |

Note: D-Nominal Outside Diameter; S-Nominal Wall Thickness

Performance Control of Steel Tube for Perforating Gun Mechanical Properties| Grade | Yield Strength (Mpa) | Tensile Strength (Mpa) | Ductility (%) | Impact Toughness(J)10*10 | |

| Horizontal | Longitudinal | ||||

| 110 | ≥ 758 | ≥ 890 | ≥ 17 | 42 | 84 |

| 130 | ≥ 896 | ≥ 931 | ≥ 15 | 45 | 90 |

| 145 | ≥ 1000 | ≥ 1034 | ≥ 11 | 50 | 100 |

- 1. When diameter of perforating gun pipe is equal or less than 73 mm, do not shock or impact.

- 2. When diameter is more than 73 mm, do longitudinal impact.

- 3. When the outside diameter of steel tube for perforating gun is equal or more than 101.6 mm, do horizontal impact.

- 4. The experimental temperature is 0℃.

- Customers can choose TT or LC for payment.

- We use steel wires or steel strips to package perforating gun pipes. Pipe caps are used to protect the pipe ends.

- Steel tube for perforating gun is transported in bulk or in containers. Customers can choose land transportation, waterway transport or sea transportation.

Attentions In oil and gas fields, perforating gun pipe is very special different from other metal structures. Perforating projectiles or explosives detonate in a certain depth underground. This results in transient high temperature and strong impact force, breaks down the shot hole location of steel tube for perforating gun, and then shots through the rock stratum or oil and gas layer to achieve the oil and gas well perforating purpose. Therefore, relevant departments have strict requirements for the use of perforating gun pipe and clearly defines that the gun pipe is always in one-time use. Once after perforating operations, steel tube for perforating gun is used as a kind of discarded product or used by downgrade.

Payment, Packaging and TransportationFounded in 1984, TallKee Steel Tube Making Factory is a professional manufacturer of seamless steel pipes and perforating gun pipes in China. Our products mainly cover casing, tubing or oil pipe, line pipe, drill pipe, high pressure boiler pipe, marine pipe, cylinder tube, hydraulic prop tube, fluid pipe, structure pipe, etc. They have passed API 5CT, API 5L, API 5DP, CCS, LR, DNV, ABS, NK, BV, GL, PED, SGS, ISO9001:2000 and ISO14001:2004 certifications. JST steel tube for perforating gun has won widespread praise and recognition by customers.

- Home

- About Us

- - Group Overview

- - Company Profile

- - Brand Development Path

- - FAQ

- - R&D Strength

- - Project Achievements

- - Why choose us

- - Download

- News

- Products

- API 5L Line Pipe

- - Onshore Line pipe

- - Offshore Line pipe

- - Through Flowline(TFL)

- - PSL-2 Line Pipe Applied in Marine

- - Acid Corrosion Resistant PSL-2 Line Pipe

- - PSL-2 Sour Service Line Pipe

- - DNV ABS LR API Line Pipe

- - X52 X60 X70 X80 QS Line Pipe

- - Coating of Line Pipe

- API 5CT

- - API 5CT Series Coupling

- - API 5CT Series Tubing

- - API 5CT Series Casing

- - API 5CT Coupling Stock

- - API 5CT Pup Joint

- JST Special Series of Tubing and Casing

- - Perforating Gun Pipe

- - Collapse Resistant Casing

- - Ultra High-Strength Casing

- - 3Cr Corrosion Resistant Tubing & Casing

- - Anti-H2S Corrosion Tubing

- - CO2 Corrosion Resistant Tubing

- - Low Temperature Service Tubing and Casing

- - Heavy Oil Thermal Pipe

- - Premium Connection

- API 5DP Drill Pipe

- Anticorrosion Steel Pipe

- International Standard

- - ASTM/ASME Standard

- - EN Standard

- - DIN Standard

- - JIS Standard

- Steel Tube Applications

- Steel Tube Process

- Quality

- - Certificates

- - Production Process

- - Online Test

- - Physical and Chemical Test

- - Quality Assurance

- - Technical Services

- - After Service

- - Cost Savings

- Views

- - Cooperation and Communication

- - Steel-Making Mill

- - Tube-Making Mill

- - Tube Processing Mill

- - Heat Treatment Mill

- - Online Test

- - Physical and Chemical Test

- - Key Equipment

- - Products Details

- - Higher Steel Grade Product

- - Packaging and Transportation

- - Warehouse & Inventory

- Environment

- - Training

- - Work in JST

- Careers

- Contact Us

English

English Español

Español Русский

Русский العربية

العربية