PSL-2 Line Pipe Applied in Marine

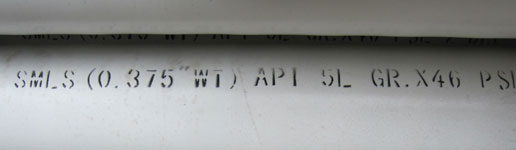

PSL 2 line pipe is typically used for transporting oil and gas in the marine environment. This marine seamless steel line pipe has good toughness, resistance to sulfide corrosion cracking (SSCC) and resistance to hydrogen-induced cracking (HIC) resistance, which improves the site weldability of steel. The higher the tempering temperature is, the lower steel tensile strength, yield strength and Vickers hardness are, but the higher the elongation and toughness are. This is conducive to be used in the marine pipelines. PSL 2 line pipe lowers carbon content and increases the quenching temperature. Based on guaranteeing hardenability, Charpy impact property of this marine seamless steel line pipe can be further improved with a lower transition temperature. The standards include DNV-OS-F101, API 5L and ISO 3183.

AdvantagesIn view of the special use environment for PSL 2 line pipe, we must carry out strict inspection, including online weld joint inspection, flattening test, hydrostatic testing, offline welding inspection, outside inspection, pipe end inspection, physical and chemical property inspection, etc.

1. JST owns a number of inspection machines for this marine seamless steel line pipe, such as Germany full spectrum direct-reading spectrometer, Japan metallurgical microscope, impact testing machine, tensile testing machine, computer controlled electro-hydraulic servo universal testing machine and a variety of machine tools. Those machines for PSL 2 line pipe can be used for stretching, flaring, squashing, curling and other physical property test of metal specimen.

2. We adopt effective weld heat treatment process. After weld heat treatment, the crystalline grain has been refined significantly with the grain size of over 9.5.

3. The introduction of an effective heat treatment process significantly improves the weld strength of this marine seamless steel line pipe. The weld strength and pipe body strength can fully meet the strength requirements of marine pipeline. In order to obtain higher weld tensile strength, we adopt special heat treatment process, making the weld strength reach the level of the pipe body, even more than the PSL 2 line pipe.

4. Toughness is an important indicator to measure the welding seam performance. As different marine seamless steel line pipes have different use states, the requirements of impact temperature are also changed accordingly. The using environment is complex and it may be impacted by sea ice and other floating debris. The ambient temperature is low, so low temperature impact toughness requirements for pipes are more stringent. JST PSL 2 line pipes can meet such requirements.

5. JST has researched the chemical composition design, metallurgy continuous casting, hot rolling process and other aspects. We adopt low-carbon, lower P, S and Mn, and add moderate Cr, Mo, Ti and other alloying elements. This can reduce composition segregation and ensure a better strength and toughness of this marine seamless steel line pipe.

6. PSL 2 line pipes carry out the second party supervision, third-party supervision and third-party inspection. Currently there are more than 10 companies in long-term resident supervision. Almost all key drill pipes are in third-party or second party supervision.

7. JST makes use of advanced ERP information management system. From batch feeding to finished marine seamless steel line pipes, we strictly implement tracking management to ensure product traceability.

8. We manufacture PSL 2 line pipes in strict accordance with quality plan. There are different quality plans for new products development, mass production of products, major products and all of the second or third-party supervised products. We also hold preparation meetings before production and issue the quality plans to the relevant quality executive departments. The executive departments should produce and inspect marine seamless steel line pipes in strict accordance with quality plans to ensure product quality.

| Standard | Grade | Mechanical Properties | ||

| Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation (A5%) | ||

| DNV-OS-F101 API 5L ISO 3183 | L245NO/BNO | 245-450 | 415-760 | ≥ 22 |

| L290NO/X42NO | 290-495 | 415-760 | ≥ 21 | |

| L360NO/X52NO | 360-565 | 460-760 | ≥ 20 | |

| L415QO/X60QO | 415-565 | 520-760 | ≥ 18 | |

| L450QO/X65QO | 450-570 | 535-760 | ≥ 18 | |

| L485QO/X70QO | 485-605 | 570-760 | ≥ 18 | |

| L555QO/X80QO | 555-675 | 625-825 | ≥ 18 | |

Technical Parameters Parameters of this marine seamless steel line pipe refer to the excel table.

Packaging and Transportation-

1. We should package PSL 2 line pipes in bundle before shipment. Each bundle should hang tags. The tag content should at least include the implementation of standards, specifications, quantity, grade, manufacturing methods, batch number, and so on.

2. Our company provides land transportation and sea transportation for customers.

TallKee Steel Tube Making Factory is a leading exporter and trader of marine seamless steel line pipes. Our company is a large scale enterprise possessing the production capacity of 600,000 tons special seamless steel pipes. We mainly manufacture PSL 2 line pipe, structure pipe, fluid pipe, high pressure boiler pipe, API pipe, alloy pipe, tubing, casing, etc. With advanced technological equipment, tremendous technical strength and reliable product quality, our marine seamless steel pipes have been exported to the Middle East, CIS, Southeast Asia, Africa, South America, North America, Europe, Australia and many other countries and regions.

- Home

- About Us

- - Group Overview

- - Company Profile

- - Brand Development Path

- - FAQ

- - R&D Strength

- - Project Achievements

- - Why choose us

- - Download

- News

- Products

- API 5L Line Pipe

- - Onshore Line pipe

- - Offshore Line pipe

- - Through Flowline(TFL)

- - PSL-2 Line Pipe Applied in Marine

- - Acid Corrosion Resistant PSL-2 Line Pipe

- - PSL-2 Sour Service Line Pipe

- - DNV ABS LR API Line Pipe

- - X52 X60 X70 X80 QS Line Pipe

- - Coating of Line Pipe

- API 5CT

- - API 5CT Series Coupling

- - API 5CT Series Tubing

- - API 5CT Series Casing

- - API 5CT Coupling Stock

- - API 5CT Pup Joint

- JST Special Series of Tubing and Casing

- - Perforating Gun Pipe

- - Collapse Resistant Casing

- - Ultra High-Strength Casing

- - 3Cr Corrosion Resistant Tubing & Casing

- - Anti-H2S Corrosion Tubing

- - CO2 Corrosion Resistant Tubing

- - Low Temperature Service Tubing and Casing

- - Heavy Oil Thermal Pipe

- - Premium Connection

- API 5DP Drill Pipe

- Anticorrosion Steel Pipe

- International Standard

- - ASTM/ASME Standard

- - EN Standard

- - DIN Standard

- - JIS Standard

- Steel Tube Applications

- Steel Tube Process

- Quality

- - Certificates

- - Production Process

- - Online Test

- - Physical and Chemical Test

- - Quality Assurance

- - Technical Services

- - After Service

- - Cost Savings

- Views

- - Cooperation and Communication

- - Steel-Making Mill

- - Tube-Making Mill

- - Tube Processing Mill

- - Heat Treatment Mill

- - Online Test

- - Physical and Chemical Test

- - Key Equipment

- - Products Details

- - Higher Steel Grade Product

- - Packaging and Transportation

- - Warehouse & Inventory

- Environment

- - Training

- - Work in JST

- Careers

- Contact Us

English

English Español

Español Русский

Русский العربية

العربية