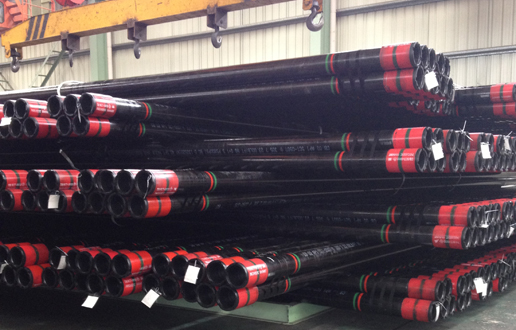

Tube Processing Mill

JST owns four tube processing lines including upsetting line, tubing threading line, casing threading line and drill pipe welding line. The annual production capacity is up to 250,000 tons of tubings and casings and 20,000 tons of drill pipes with the size of Φ60.3 mm to 339.7 mm.

Upsetting line is equipped with three sets of GTR120/160 medium frequency induction heating furnaces and one set of 630 tons of upsetting unit. The annual production reaches 20,000 tons of tubings or 10,000 tons of drill pipes.

Threading line is equipped with two sets of QK1319-G CNC casing thread machines and three sets of Q1334H tubing thread machines, featuring high precision and high strength. Three domestic advanced hydrostatic machines can test tubes of Φ60 mm to 406 mm with the maximum pressure of 120 Mpa. Two sets of magnetic powder detection machines are aimed to check crack defects inside and outside within 500 mm away from the tube ends. It can process 180,000 tons of tubings and 70000 tons of casings every year.

Drill pipe welding line is equipped with one set of CG1600 inertial friction welder, 9 sets of Q1319-1A pipe threading machines, two sets of QK1319-A CNC pipe threading lathes, 7 sets of medium frequency induction heat treatment furnaces and one set of inner bore sharpening machine. The annual production of drill pipe is 20,000 tons.

- Home

- About Us

- - Group Overview

- - Company Profile

- - Brand Development Path

- - FAQ

- - R&D Strength

- - Project Achievements

- - Why choose us

- - Download

- News

- Products

- API 5L Line Pipe

- - Onshore Line pipe

- - Offshore Line pipe

- - Through Flowline(TFL)

- - PSL-2 Line Pipe Applied in Marine

- - Acid Corrosion Resistant PSL-2 Line Pipe

- - PSL-2 Sour Service Line Pipe

- - DNV ABS LR API Line Pipe

- - X52 X60 X70 X80 QS Line Pipe

- - Coating of Line Pipe

- API 5CT

- - API 5CT Series Coupling

- - API 5CT Series Tubing

- - API 5CT Series Casing

- - API 5CT Coupling Stock

- - API 5CT Pup Joint

- JST Special Series of Tubing and Casing

- - Perforating Gun Pipe

- - Collapse Resistant Casing

- - Ultra High-Strength Casing

- - 3Cr Corrosion Resistant Tubing & Casing

- - Anti-H2S Corrosion Tubing

- - CO2 Corrosion Resistant Tubing

- - Low Temperature Service Tubing and Casing

- - Heavy Oil Thermal Pipe

- - Premium Connection

- API 5DP Drill Pipe

- Anticorrosion Steel Pipe

- International Standard

- - ASTM/ASME Standard

- - EN Standard

- - DIN Standard

- - JIS Standard

- Steel Tube Applications

- Steel Tube Process

- Quality

- - Certificates

- - Production Process

- - Online Test

- - Physical and Chemical Test

- - Quality Assurance

- - Technical Services

- - After Service

- - Cost Savings

- Views

- - Cooperation and Communication

- - Steel-Making Mill

- - Tube-Making Mill

- - Tube Processing Mill

- - Heat Treatment Mill

- - Online Test

- - Physical and Chemical Test

- - Key Equipment

- - Products Details

- - Higher Steel Grade Product

- - Packaging and Transportation

- - Warehouse & Inventory

- Environment

- - Training

- - Work in JST

- Careers

- Contact Us

English

English Español

Español Русский

Русский العربية

العربية